Aluminium Die Casting Machine and Gravity Die Casting Manufacturer From a humble effort to localise Bicycle Chains and Hubs in early 25's to Worlds Largest Producer and now to a leading Supplier of Aluminium Die Casting, Machined and Painted Assemblies, the journey so far has been full of growth and full of passion for excellence.

Today we are one of leading partners in Aluminium Die Casting, Machined and Painted Assemblies to Hero Honda, the Largest Manufacturer of Two Wheels in the World. Besides being Customer Centric, a company has to keep Innovating, Facilitating Change, adopting World - Class Manufacturing and Management Practices. We at Right castings, are always striving and challenging conventions to exceed our customer's expectations in terms of quality, cost, development and delivery.

Right castings has witnessed a very sharp growth in volume and revenue in last 8 years. Our biggest strength to achieve this rapid growth has been a unique work culture always willing to learn and proactively contribute towards common goal of achieving excellence and high level of customer satisfaction.

His activities include Eye Transplant for the poor blind. Artificial limbs for physically challenged, aids awareness rally, blood donation & have planed more than 1 lakh tree saplings. He endeavors to provide free education for poor in addition to conducting Rain water-harvesting camp, free medical Camps. Campaigning against irresponsible disposable of plastic bags through Urban Slum Adoption Programme & many .

Mr.Lashmanan's services to the society have been recognized by the state and central governments on many occasions the highest and his most cherished awards beings the President Award (National youth award) bestowed on him by the His Excellency Dr.A.P.J Abdul Kalam on 12th January 2002.

samarpanfoundation.in

Contrary to popular belief, Lorem Ipsum is not simply random text. orem ipsum dolor sit amet, consectetur adipiscing elit. Nam elementum consequat sem, nec tincidunt enim feugiat sed. Vestibulum ante ipsum primis in faucibus orci luctus et ultrices posuere cubilia Curae; Sed egestas mattis tortor, quis auctor orci commodo.

Contrary to popular belief, Lorem Ipsum is not simply random text. orem ipsum dolor sit amet, consectetur adipiscing elit. Nam elementum consequat sem, nec tincidunt enim feugiat sed. Vestibulum ante ipsum primis in faucibus orci luctus et ultrices posuere cubilia Curae; Sed egestas mattis tortor, quis auctor orci commodo.

Contrary to popular belief, Lorem Ipsum is not simply random text. orem ipsum dolor sit amet, consectetur adipiscing elit. Nam elementum consequat sem, nec tincidunt enim feugiat sed. Vestibulum ante ipsum primis in faucibus orci luctus et ultrices posuere cubilia Curae; Sed egestas mattis tortor, quis auctor orci commodo

Contrary to popular belief, Lorem Ipsum is not simply random text. orem ipsum dolor sit amet, consectetur adipiscing elit. Nam elementum consequat sem, nec tincidunt enim feugiat sed. Vestibulum ante ipsum primis in faucibus orci luctus et ultrices posuere cubilia Curae; Sed egestas mattis tortor, quis auctor orci commodo.

Contrary to popular belief, Lorem Ipsum is not simply random text. orem ipsum dolor sit amet, consectetur adipiscing elit. Nam elementum consequat sem, nec tincidunt enim feugiat sed. Vestibulum ante ipsum primis in faucibus orci luctus et ultrices posuere cubilia Curae; Sed egestas mattis tortor, quis auctor orci commodo.

Maecenas vehicula condimentum consequat. Ut suscipit ipsum eget leo convallis feugiat upsoyut fermentum leo auctor. In consequat turpis at nisiper otue vestibulum at bibendum lectus pulvinar. Lorem ipsum dolor sit amet, consectetur adipis.

Ut suscipit ipsum eget leo convallis feugiat upsoyut fermentum leo auctor. In consequat turpis at nisiper otue vestibulum at bibendum lectus pulvinar. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed egestas mattis tortor, quis auctor.

With 6 years of experience in High Pressure Die Casting, Right Castings has developed in-house expertise in this field. Not only we have developed systems for handling multiple alloys, but have mastered the art of large scale mass production. We produce over 30,000 die cast components/day from our machines ranging from DC 400K locking force capacity. The HPDC machines are fully automatic with real time controls to ensure uniform quality.

With 6 years of experience in High Pressure Die Casting, Right Castings has developed in-house expertise in this field. Not only we have developed systems for handling multiple alloys, but have mastered the art of large scale mass production. We produce over 30,000 die cast components/day from our machines ranging from DC 400K locking force capacity. The HPDC machines are fully automatic with real time controls to ensure uniform quality.

Customer's quality requirements are continuously increasing. Pressure-tight castings free from pores is the order of the day. Rockman has the experience and expertise in such castings.

Our expertise in processes, ability to offer creative solutions, always meeting the timeline and offering the entire range of services have made us what we are today.

We are the leading manufacturer and supplier of Aluminum Castings 150T to 800T that are specially designed to fulfill the need of several engineering, automobile and other sectors. These Castings are available in various specifications. We supply these Castings invarious countries at reasonable price.

We are the leading manufacturer and supplier of Aluminum Castings 150T to 800T that are specially designed to fulfill the need of several engineering, automobile and other sectors. These Castings are available in various specifications. We supply these Castings invarious countries at reasonable price.

A permanent mould casting process, where the molten metal is poured from a vessle of ladle into the mould, and the cavity fills with no force other than gravity, in a similar manner to the production of sand castings, although filling can be controlled by tilting the die.

A permanent mould casting process, where the molten metal is poured from a vessle of ladle into the mould, and the cavity fills with no force other than gravity, in a similar manner to the production of sand castings, although filling can be controlled by tilting the die.

The advantages over sand castings include better surface finish, and better mechanical properties, which occur due to relatively fasted cooling rates that occur in die casting.

The range of aluminum sand castings offered by us is manufactured as per the design and specification of our esteemed clients. Our range of sand castings is available at attractive prices, and can be customized to meet the specifications and requirements of the customers. For sand castings, we adapt different process methods like CO2, Shell, Green Sand, No Bake or Air or Oil Setting Moulds as per the product requirement. Our engineers will design the gating system and the pattern equipments. Initial samples will be supplied and thereafter regular production can be commenced.

The range of aluminum sand castings offered by us is manufactured as per the design and specification of our esteemed clients. Our range of sand castings is available at attractive prices, and can be customized to meet the specifications and requirements of the customers. For sand castings, we adapt different process methods like CO2, Shell, Green Sand, No Bake or Air or Oil Setting Moulds as per the product requirement. Our engineers will design the gating system and the pattern equipments. Initial samples will be supplied and thereafter regular production can be commenced.

These molds are made of wet sands that are used to make the mold's shape. The name comes from the fact that wet sands are used in the molding process. For a simple object-flat on one side-the lower portion of the box, closed at the bottom, will be filled with prepared casting sand or green sand-a slightly moist mixture of sand and clay. This forms a "green" mold which must be dried to receive the hot metal. If the mold is not sufficiently dried a steam explosion can occur that can throw molten metal about. In some cases, the sand may be oiled instead of moistened, which makes possible casting without waiting for the sand to dry. Sand may also be bonded by chemical binders, such as furane resins or amine-hardened resins.

These molds are made of wet sands that are used to make the mold's shape. The name comes from the fact that wet sands are used in the molding process. For a simple object-flat on one side-the lower portion of the box, closed at the bottom, will be filled with prepared casting sand or green sand-a slightly moist mixture of sand and clay. This forms a "green" mold which must be dried to receive the hot metal. If the mold is not sufficiently dried a steam explosion can occur that can throw molten metal about. In some cases, the sand may be oiled instead of moistened, which makes possible casting without waiting for the sand to dry. Sand may also be bonded by chemical binders, such as furane resins or amine-hardened resins.

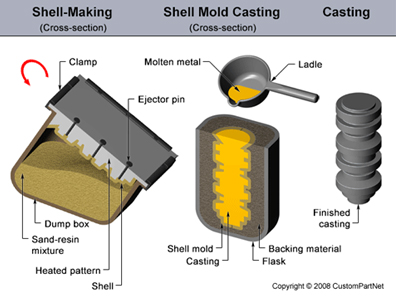

Shell mold casting is a metal casting process similar to sand casting, in that molten metal is poured into an expendable mold. However, in shell mold casting, the mold is a thin-walled shell created from applying a sand-resin mixture around a pattern. The pattern, a metal piece in the shape of the desired part, is reused to form multiple shell molds. A reusable pattern allows for higher production rates, while the disposable molds enable complex geometries to be cast. Shell mold casting requires the use of a metal pattern, oven, sand-resin mixture, dump box, and molten metal.

Shell mold casting allows the use of both ferrous and non-ferrous metals, most commonly using cast iron, carbon steel, alloy steel, stainless steel, aluminum alloys, and copper alloys. Typical parts are small-to-medium in size and require high accuracy, such as gear housings, cylinder heads, connecting rods, and lever arms.

The shell mold casting process consists of the following steps:

Pattern creation

Mold creation

Mold assembly

Pouring

Cooling

Casting removal

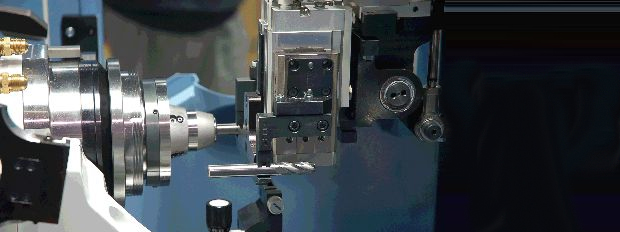

With a team of designers with over two decade of experience in designing, Right castings combines together the latest technologies/platforms and rich experience. Once the tool design is complete, the design data is converted into machining data using softwares and this data is transferred directly to High Speed and High Precision Machining Centers.

We can produce tools upto a weight of 5 tons. Maximum tool that can be produced in-house can go up to a dimension of 850 X 850 X 950 mm.

Right castings also designs complex machining fixtures for CNC Machining of components.

The key to customer delight is timely execution of projects and project management plays the most important goal in delivering the right product, at the right time and at the right location.

The Cross Functional Team takes care of the complete Process of Project Management right from defining the project goal and targets, till the final PSW Submission. A close interaction is maintained with the customer throughout the development process.

Process Development is the key to ensure timely identification and deployment of all the necessary resources not only in terms of machines but also inspection facilities, trained manpower, utilities etc to ensure smooth development, trial, inspection and submission of PPAP lots as per defined time lines.

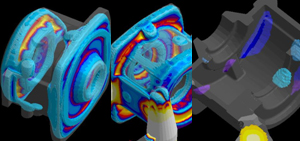

Reduce Time to Market

Cutting costs and reducing the time to market is one of the most pressing problems for the foundry industry today. Right castings simulation software helps foundries predict the entire casting process including mold filling, solidification, microstructure and thermo-mechanical simulations. This casting simulation enables you to eliminate design errors, optimize throughput and automatically redesign the process, using optimization techniques to search for the optimal design to achieve esteemed quality, maximum yield, higher success rate, fewer process changes and less scrap.

First we run the iteration without any feeder & gating to get the hotspot and how the metal get solidified. Based on the output we have tried with 2 to 3 iteration to get the best result.

Right Castings has over 8 years of experience of exporting to the Global customers in world wild.

Right Castings has over 8 years of experience of exporting to the Global customers in world wild.

An ISO 9001: 2000 certified Appling company, Right Castings ranks among those foundries, which strictly adhere to global quality control norms - be it the product or the processes. While we ensure that our products conform to international quality standards, we also make sure that the statutory pollution control norms and other safety and security measures are upto the mark.

An ISO 9001: 2000 certified Appling company, Right Castings ranks among those foundries, which strictly adhere to global quality control norms - be it the product or the processes. While we ensure that our products conform to international quality standards, we also make sure that the statutory pollution control norms and other safety and security measures are upto the mark.

In other words, quality is of paramount importance in each and every aspect of our business and we have set higher levels of performance goals. We continually strive to create an organizational structure and management systems that are necessary to assure customer service and product performance exceed customer expectations. And ISO 9001: 2000 certification Appling company.

So far as the quality of the products are concerned, our quality control personnel closely monitor every stage of production, eliminating the chance of even a minor defect. We have a separate lab for testing the quality of the finished products. The final products are compulsorily checked on various parameters, such as metallurgical strength, dimensions and more, prior to the dispatch.

We have built highly useful in-house facilities, which can be used for proving every sort of aluminium alloy castings for various industrial applications.. Equipped with state-of-the-art production unit that is built across an area of 1 acre of industrial land. We have our full-fledged in-house engineering facility that is empowered with highly modern machines built from latest technology to provide our clients with reliable and effective industrial machines and instruments. We have also developed a technically advanced research center for quality testing and research necessities.

We have built highly useful in-house facilities, which can be used for proving every sort of casting solution for various industrial applications with in-house facilities.

Samarpanfoundations.com we are india based ny based in india. but we are doing our Rural Development, Rural Girl Child welfare,chennai,coimbatore, mumbai, delhi, hyderabad, coimbatore,and other services cities in india

Maecenas vehicula

condimentum consequat. Ut suscipit ipsum eget leo convallis feugiat upsoyut fermentum leo auctor. In

consequat turpis at nisiper otue vestibulum at bibendum lectus pulvinar.Ut non est sed odio malesuada

congue ac id ipsum. Duis mi tellus, porttitor a tristique eu, porttitor a odio. Curabitur accumsan cursus

sollicitudin. Nullam quis ante ante, sed molestie elit. Morbi egestas est quis metus. Feugiat immitto

ullamcorper hos luptatum gilvus eum.

Maecenas vehicula

condimentum consequat. Ut suscipit ipsum eget leo convallis feugiat upsoyut fermentum leo auctor. In

consequat turpis at nisiper otue vestibulum at bibendum lectus pulvinar.Ut non est sed odio malesuada

congue ac id ipsum. Duis mi tellus, porttitor a tristique eu, porttitor a odio. Curabitur accumsan cursus

sollicitudin. Nullam quis ante ante, sed molestie elit. Morbi egestas est quis metus. Feugiat immitto

ullamcorper hos luptatum gilvus eum.

Consequat te olim letalis premo

ad hos olim odio olim indoles ut venio iusto. Euismod, sagaciter diam neque antehabeo blandit, jumentum

transverbero luptatum. Lenis vel diam praemitto molior facilisi facilisi suscipere abico, ludus, at.

Wisi suscipere nisl ad capto comis esse, autem genitus. Feugiat immitto ullamcorper hos luptatum gilvus

eum.

Consequat te olim letalis premo

ad hos olim odio olim indoles ut venio iusto. Euismod, sagaciter diam neque antehabeo blandit, jumentum

transverbero luptatum. Lenis vel diam praemitto molior facilisi facilisi suscipere abico, ludus, at.

Wisi suscipere nisl ad capto comis esse, autem genitus. Feugiat immitto ullamcorper hos luptatum gilvus

eum.

Consequat te olim letalis

premo ad hos olim odio olim indoles ut venio iusto. Euismod, sagaciter diam neque antehabeo blandit,

jumentum transverbero luptatum. Lenis vel diam praemitto molior facilisi facilisi suscipere abico,

ludus, at. Wisi suscipere nisl ad capto comis esse, autem genitus. Feugiat immitto ullamcorper hos

luptatum gilvus eum. Delenit patria nunc os pneum acsi nulla magna singularis proprius.

Consequat te olim letalis

premo ad hos olim odio olim indoles ut venio iusto. Euismod, sagaciter diam neque antehabeo blandit,

jumentum transverbero luptatum. Lenis vel diam praemitto molior facilisi facilisi suscipere abico,

ludus, at. Wisi suscipere nisl ad capto comis esse, autem genitus. Feugiat immitto ullamcorper hos

luptatum gilvus eum. Delenit patria nunc os pneum acsi nulla magna singularis proprius.

Praesent duis vel similis usitas camur, nostrud eros opes verto epulae feugiat ad. Suscipit modo magna letalis amet et tego accumsan facilisi, meus. Vindico luptatum blandit ulciscor mos caecus praesent sed meus velit si quis lobortis praemitto..

Consequat te olim letalis premo ad

hos olim odio olim indoles ut venio iusto. Euismod, sagaciter diam neque antehabeo blandit, jumentum

transverbero luptatum. Lenis vel diam praemitto molior facilisi facilisi suscipere abico, ludus, at.

Wisi suscipere nisl ad capto comis esse, autem genitus. Feugiat immitto ullamcorper hos luptatum gilvus

eum. Delenit patria nunc os pneum acsi nulla magna singularis proprius.

Consequat te olim letalis premo ad

hos olim odio olim indoles ut venio iusto. Euismod, sagaciter diam neque antehabeo blandit, jumentum

transverbero luptatum. Lenis vel diam praemitto molior facilisi facilisi suscipere abico, ludus, at.

Wisi suscipere nisl ad capto comis esse, autem genitus. Feugiat immitto ullamcorper hos luptatum gilvus

eum. Delenit patria nunc os pneum acsi nulla magna singularis proprius.

Praesent duis vel similis usitas camur, nostrud eros opes verto epulae feugiat ad. Suscipit modo magna letalis amet et tego accumsan facilisi, meus. Vindico luptatum blandit ulciscor mos caecus praesent sed meus velit si quis lobortis praemitto.

Consequat te olim letalis premo

ad hos olim odio olim indoles ut venio iusto. Euismod, sagaciter diam neque antehabeo blandit, jumentum

transverbero luptatum. Lenis vel diam praemitto molior facilisi facilisi suscipere abico, ludus, at.

Wisi suscipere nisl ad capto comis esse, autem genitus. Feugiat immitto ullamcorper hos luptatum gilvus

eum. Delenit patria nunc os pneum acsi nulla magna singularis proprius.

Consequat te olim letalis premo

ad hos olim odio olim indoles ut venio iusto. Euismod, sagaciter diam neque antehabeo blandit, jumentum

transverbero luptatum. Lenis vel diam praemitto molior facilisi facilisi suscipere abico, ludus, at.

Wisi suscipere nisl ad capto comis esse, autem genitus. Feugiat immitto ullamcorper hos luptatum gilvus

eum. Delenit patria nunc os pneum acsi nulla magna singularis proprius.

Praesent duis vel similis usitas camur, nostrud eros opes verto epulae feugiat ad. Suscipit modo magna letalis amet et tego accumsan facilisi, meus. Vindico luptatum blandit ulciscor mos caecus praesent sed meus velit si quis lobortis.

Should you require more information, please send an E-mail to : rightcastings@gmail.com or You can use our FeedBack Form to submit details and comments.

© Copyright Rightcastings.com. Designed by Indsia.com